A pink sapphire. All those indents at the surface must be sloughed off. Notice how the outline shape is irregular. We’ve got to even it out and aim for a rectangle

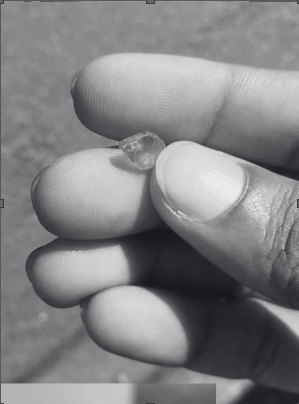

Notice how small it has become.This depends on how much meat there is to the stone. That is how much base, you can obtain without making the stone go flat.

I wish I could have taken a picture of this before heating it. Imagine a very pale blue stone.

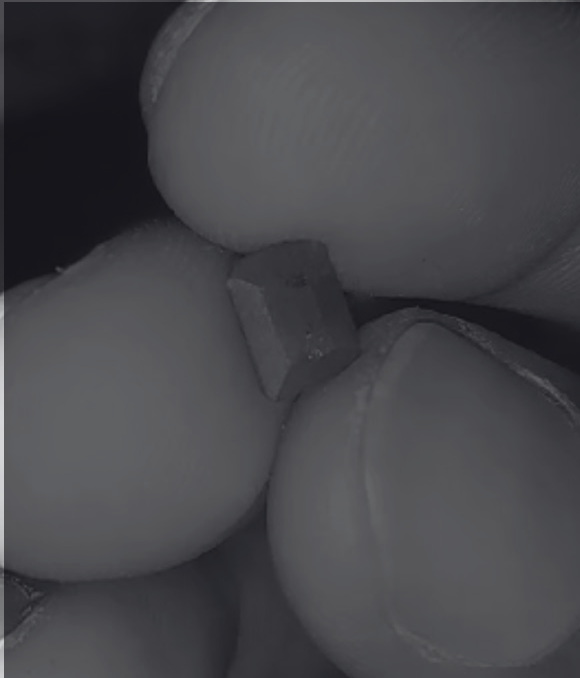

This rough stone weighed about 3 carats. And notice the white inclusions protruding inwards from the lower end. The goal is to slough these off, and make them less noticeable in the faceted gemstone.

Here is the same stone, after cutting. Its now got a lighter shade of blue compared to the rough stone. Why is this?

The parts of the stone responsible for the darker shade of blue were superficially located and were thus sloughed off.

Now here’s the final product. It wasn’t perfect. Not the shade of blue we wanted. And much smaller than expected.

Beautiful, nevertheless.

Another pink sapphire. As the size of this rough stone is already small, we had to go for the shape most closest to its outline. That is a pear/ drop shape. Sadly this shape isn’t common and the market for it is less.

This is an example of a stone in which we didn’t succeed. We opted to heat it, resulting in it being blasted to smithereens. That happens, occasionally.

Some of the key pointers we have to consider are

The basic shape of the rough stone

The types of inclusions in them

Size…

Possible changes in color

One Response